STEP 1:Join our Facebook Group

STEP 1:Join our Facebook Group

Enter the M1200 Laser Welder giveaway.

We’ll announce the draw time and the winners directly in the group.

STEP 2:Register Your Email

STEP 2:Register Your Email

Get an €800 coupon after signing up.

required for the draw — don’t skip!

Lock in Rewards Now

Lock in Rewards Now

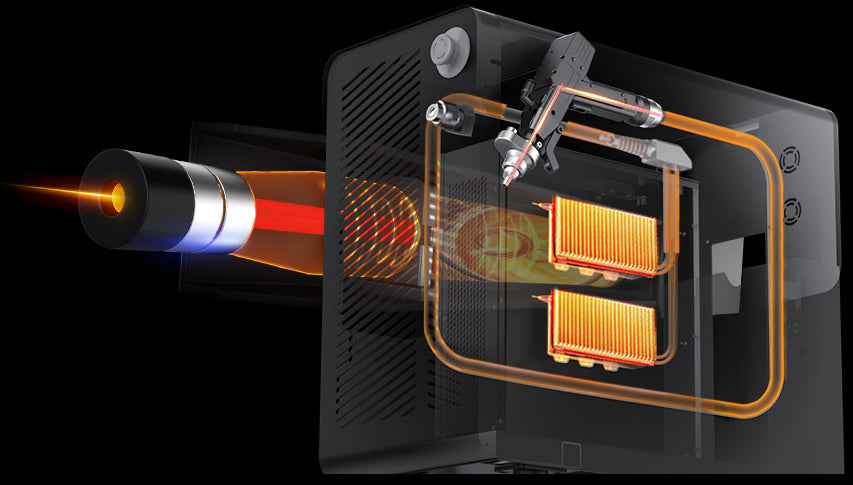

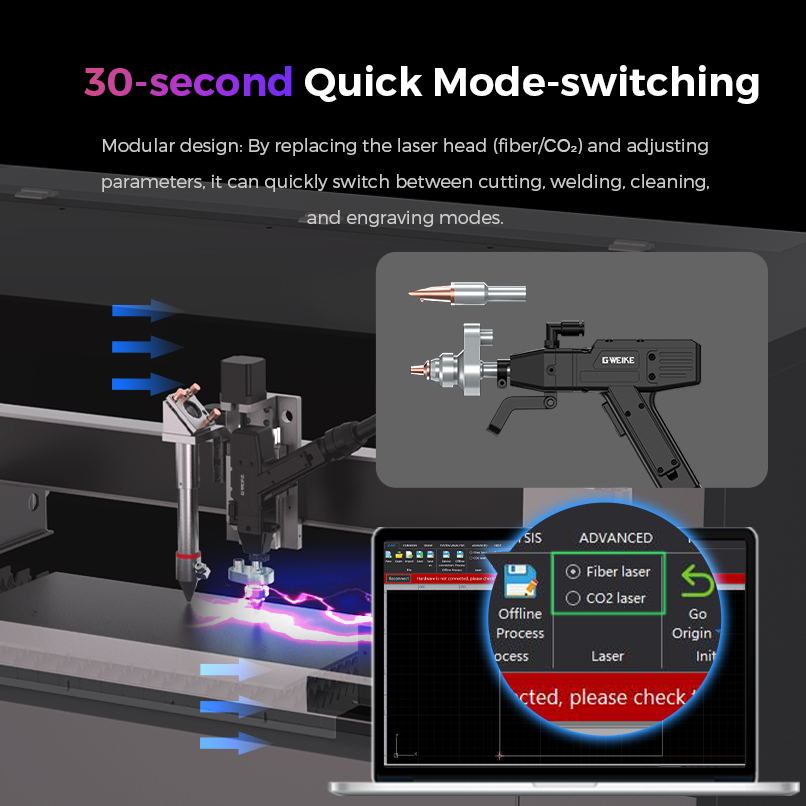

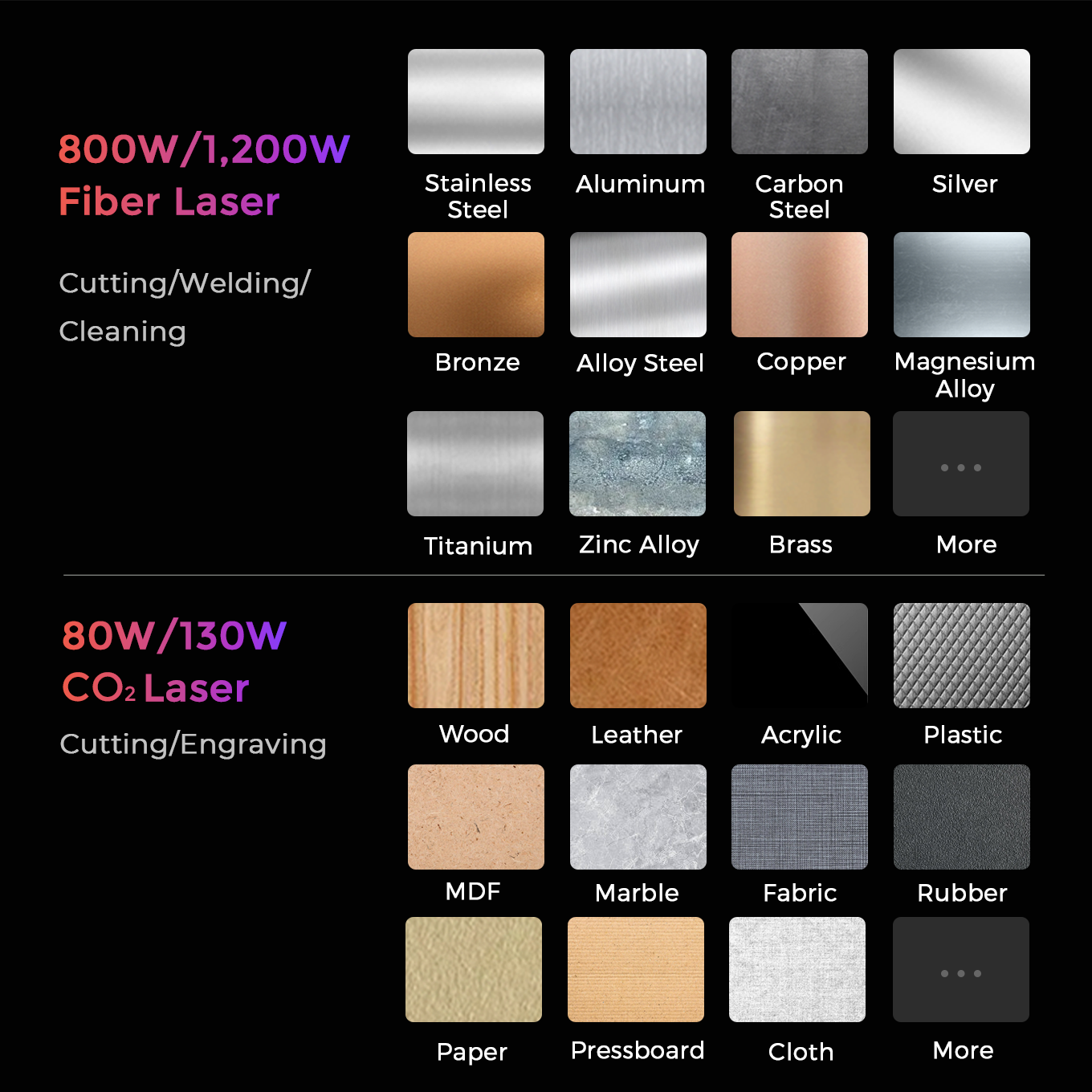

M1200 Laser Welder!

M1200 Laser Welder!